FRP Pultruded Profile Providers from India

Fiber-reinforced polymer (FRP) pultruded profiles are revolutionizing diverse industries in India. Offering superior strength, corrosion resistance, and lightweight properties, they are a versatile and preferred choice for various applications. Here in India, we have a thriving community of FRP pultruded profile manufacturers crafting innovative and high-quality products. Saumit is committed to serving the needs of domestic and international clients across various sectors.

What is FRP Pultruded Profiles?

Unmatched Quality and Precision

Benefits of Choosing FRP Pultruded Profiles sourced from Saumit

- Vast Expertise: Saumit possesses extensive experience and knowledge in crafting FRP pultruded profiles, ensuring consistent quality and adherence to specific industry standards.

- Diverse Product Range: From standard profiles to custom-designed solutions, Saumit offers a wide variety of options to cater to your specific project requirements.

- Cost-Effectiveness: Compared to our international counterparts, we often provide competitive pricing, making our products a budget-friendly option without compromising on quality.

Types of Pultruded Profile

Square Box Pipe

C-Channel

L-Angle

Rectangular Box Pipe

Round Tube

I-Beam

FRP Pultruded Profiles FAQs

1. How Durable are FRP Pultruded Profiles?

FRP pultruded profiles are known for their durability. They resist impact, fatigue, and wear over time, making them suitable for demanding environments. Their non-corrosive nature ensures they retain their strength and aesthetic appeal even after prolonged exposure to moisture, chemicals, and UV rays.

2. Are FRP Pultruded Profiles Environmentally Friendly?

Yes, FRP pultruded profiles are environmentally friendly. They are made from sustainable materials such as glass fibers and resins, and their production process produces minimal waste. Additionally, FRP profiles are fully recyclable at the end of their life cycle, contributing to a more sustainable environment.

3. How Can I Maintain FRP Pultruded Profiles?

Maintaining FRP profiles is easy due to their low maintenance needs. Simple cleaning with water and mild detergents is often enough to keep them looking like new. For applications exposed to harsh conditions, periodic inspections are recommended to ensure that they are in optimal condition.

4. Are FRP Pultruded Profiles Cost-Effective?

While the initial investment in FRP pultruded profiles can be higher than traditional materials, the long-term savings are significant. Due to their low maintenance requirements, durability, and resistance to corrosion, the total cost of ownership is lower, making them an economically sound choice in the long run.

5. Can FRP Pultruded Profiles Be Custom Designed?

Yes, FRP pultruded profiles can be custom-designed to meet specific project requirements. The pultrusion process allows manufacturers to create profiles in various shapes, sizes, and lengths, providing flexibility in design for different applications.

- Advantages

- Applications

- Size Chart

- Resin System

Advantages

- Corrosion Resistant

- Low Maintenance

- Fire Retardant

- High Strength

- Lightweight

- Impact Resistant

- Long service Life

- No need to paint every year

Applications

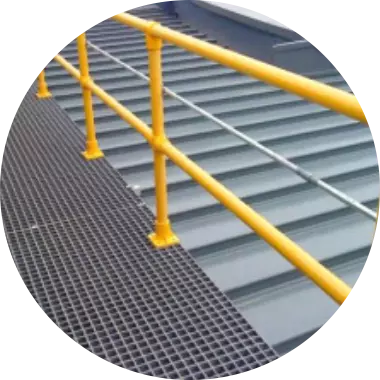

Industrial Handrails

Industrial Ladder

Industrial FRP Structure

Solar Panel Mounting Structure

Size Availability

| SR. NO. | Structural Profile Description | Profile Details | ||

|---|---|---|---|---|

| Width Of Profile mm |

Height of Profile mm |

Thickness of Profile mm |

||

| 1 | Notch Bar/ Groove Bar | |||

| 2 | HAT 80 (Midrail) | 80 | 32 | 3 |

| 3 | Kick Plate | 101 | 15 | 3 |

| 4 | Omega | 65 | 50 | 4 |

| 5 | Square Tube | 40 | 40 | 3 |

| 50 | 50 | 4 | ||

| 5 | ||||

| 63.5 | 63.5 | 5 | ||

| 76.2 | 76.2 | 6 | ||

| 5 | ||||

| 88.9 | 88.9 | 3.175 | ||

| 5 | ||||

| 6 | Square Rung | 25 | 25 | 3 |

| 7 | C-Channel | 50 | 30 | 3 |

| 50 | 50 | 3 | ||

| 4 | ||||

| 58 | 12 | 3 | ||

| 75 | 30 | 3 | ||

| 4 | ||||

| 5 | ||||

| 100 | 30 | 4 | ||

| 5 | ||||

| 6 | ||||

| 100 | 20 | 3 | ||

| 100 | 50 | 3 | ||

| 4 | ||||

| 108 | 15 | 3 | ||

| 150 | 50 | 3 | ||

| 6 | ||||

| 150 | 50 | 4 | ||

| 8 | Equal Angle | 29 | 29 | 3 |

| 50 | 50 | 6 | ||

| 9 | I Beam | 152.4 | 76.2 | 6.35 |

| 8 | ||||

| 38 | 15 | 4 | ||

| 10 | Fluted Pipe / Serrated Pipe | 32 | 5 | |

| 11 | Flat Bar | 100 | 4 | |

| 12 | Carrier Profile | 64 | 64 | 4 |

| 13 | Deck Panel | 610 | 29 | 4.5 |

Resin Systems

| Resin Type | Resin Base | Properties | Description |

|---|---|---|---|

| SIGPL – O | Orthopthalic Polyester Resin | UV | General Purpose with UV resistivity |

| SIGPL – OFR | Orthopthalic Polyester Resin | UV + FR | General Purpose with UV resistivity and fire retardance (UL – 94) |

| SIGPL – I | Isopthalic Polyester Resin | UV | Industrial Grade Corrosion Resistant |

| SIGPL – IFR | Isopthalic Polyester Resin | UV + FR | Industrial Grade Corrosion Resistant and fire retardant (UL-94 and ASTM E84) |

| SIGPL – V | Vinyl Ester Resin | UV + FR | Higher Corrosion Resistant and Fire retardent (UL-94 and ASTM E84) |

| SIGPL – VS | Super Vinyl Ester Resin | UV + FR | Highest Corrosion Resistant and Fire retardent (UL-94 and ASTM E84) |